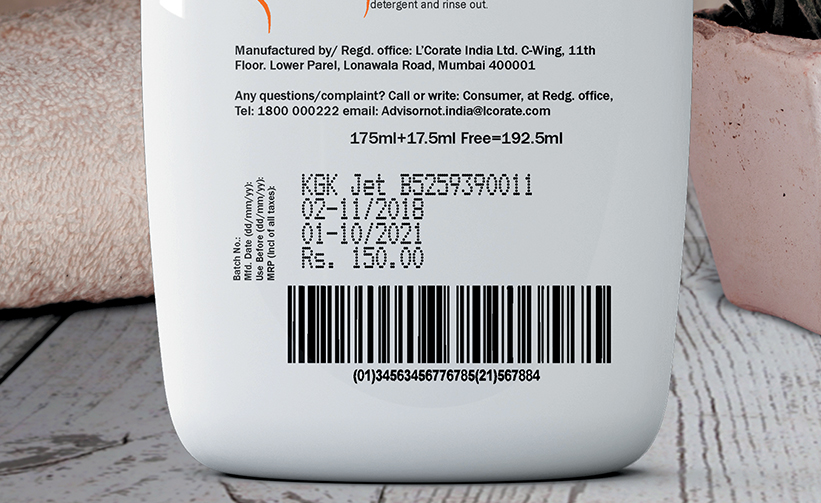

How KGK Jet CIJ, Laser, and DOD Batch Coding Machines Keep Pace with Personal Care Packaging Production

In the competitive world of personal care product manufacturing, maintaining high-speed, precise, and reliable marking and coding is essential. From shampoo bottles and lotion tubes to cartons and bulk packaging, every product must carry accurate information such as batch codes, expiry dates, and traceability details. This is where KGK Jet’s range of CIJ, Laser, and Drop on Demand (DOD) Batch Coding Machines excel — ensuring seamless integration across primary and tertiary packaging lines.

Coding Solutions for Every Packaging Stage

KGK Jet offers a comprehensive range of batch coding

machines designed to meet the complex requirements of personal care

packaging.

- Continuous

Inkjet Printers (CIJ): Ideal for primary packaging such as

bottles, tubes, jars, and sachets. KGK CIJ printers deliver high-speed,

consistent printing even on curved, glossy, or irregular surfaces — common

in personal care products.

- Laser

Marking Machines: For permanent, tamper-proof marking on plastic,

glass, or metal surfaces. The laser solution ensures the code never fades,

even under moisture, oil, or cosmetic exposure.

- Drop

on Demand (DOD) Printers: Perfect for tertiary packaging

applications like cartons, corrugated boxes, and shipping cases. With

high-resolution prints and bold characters, DOD printers make logistics

and inventory management effortless.

Inks for Every Substrate

KGK Jet understands that personal care packaging involves a

wide range of materials — from glossy plastic and laminated tubes to paperboard

cartons. That’s why the company offers a range of inks for multiple

substrates, ensuring perfect adhesion and legibility on every surface.

The extensive range of dye and pigment-based inks, originally designed

for demanding industries like dairy, also performs exceptionally well in the

personal care segment. Whether printing on transparent PET bottles or coated

labels, KGK inks guarantee sharp, durable, and smudge-free codes.

Quick Line Changeover for Flexible Production

Modern personal care manufacturers often switch between

different packaging types and sizes. KGK Jet’s versatile batch coding

machines enable quick line changeovers, applying codes to bottle

caps, container bases, labels, or directly onto packaging surfaces. This

flexibility ensures minimal downtime and maximum productivity — a must for

high-speed, multi-SKU production environments.

Combating Counterfeiting with Fluorescent Inks

Counterfeit and fake products are a growing concern in the

personal care industry. KGK Jet addresses this challenge with specialised

invisible fluorescent inks that are visible only under UV light. This

security feature helps brand owners authenticate genuine products and

protect consumer trust.

Simultaneous Control of Up to 16 Units

KGK Jet’s advanced control architecture allows one master

unit to manage up to 16 slave units simultaneously. This is ideal for

large-scale production lines running multiple packaging lanes. Centralised

control simplifies operation, improves synchronization, and ensures consistent

print quality across all lines.

Fastest Start-Up in the Industry

Production efficiency often depends on how quickly the

printer can get ready for use. With KGK’s nozzle capping technology,

there’s no need to flush ink with solvent, reducing wastage and

downtime. The world’s fastest batch coding machine can start printing in

just 24 seconds from a stopped state, and resume in about 16 seconds

after brief halts — keeping pace with even the most demanding production

schedules.

Conclusion

From compact CIJ and Laser printers for primary

packaging to DOD printers for tertiary applications, KGK Jet provides

complete, high-performance batch coding solutions for the personal care

industry. With advanced ink options, rapid start-up, multi-line control, and

anti-counterfeiting features, KGK Jet’s machines not only ensure compliance and

traceability but also enhance operational efficiency.

Whether your goal is to print expiry codes on lotion tubes

or brand logos on shipping cartons, KGK Jet’s Batch Coding Machines are

built to keep up with your production — and your growth.

Subscribe to our newsletter and receive a selection of cool articles every weeks

The Latest

Tough Environments Strong Codes KGK Jet CIJ and Laser Printers for Agrochemical Packaging

09 June 2025

![]() 2 minute read

2 minute read

How KGK Jet CIJ and Marking Laser Technology Stay Aligned with Food Packaging for Products with Short Shelf Life

11 September 2024

![]() 2 minute read

2 minute read